Laser-based methods

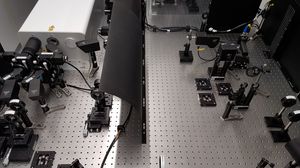

RhySearch's climate-controlled laser laboratory offers a wide range of laser-based methods for testing and qualifying optical components. Our division has become an established source for laser-induced damage threshold testing, optical loss measurements, scattering loss measurements, and general metrology of optical components. Thanks to a wide range of specialized optical instruments and laser sources and our years of experience, we can thus support you in a broad spectrum of optical test and measurement requirements.

All equipment is also available for service orders.

For further information, advice or questions, please contact our experts.

Contact

Laser-Induced Deflection (LID)

RhySearch utilizes a Laser Absorption Measurement System. The absorption of coatings can lead to various undesirable effects, such as laser-induced damage, thermal lenses/focus shifts, reduced long-term stability, or wavefront deformations. Absorption measurements of optical coatings provide an additional data point to the Total Scatter and Angle-Resolved Scatter measurements.

Laser Induced Damage Threshold (LIDT)

RhySearch's LIDT measurement system provides destructive testing of the laser resistance of optical components. The LIDT tests can be performed according to ISO standard 21254 or with other methods if needed. The tests can be performed with the following laser sources:

High energy ns-pulsed Nd:YAG DPPS laser source:

- Wavelengzh 355 nm, 532 nm and 1064 nm (linearly polarized)

- Effective pulse duration (Half-width): 10 ns

- Pulse energies: 350 mJ, 180 mJ, 90 mJ (1064 nm, 532 nm, 355 nm)

- Gaussian profile in the focal plane

- Repetition rate till 100 Hz

Femtosecond laser source:

- Wavelength 1030 nm

- Effective pulse duration (Half-width): 400 fs

- Gaussian profile in the focal plane

- Repetition rate 50 kHz.

For your quote request: Form LIDT-Test

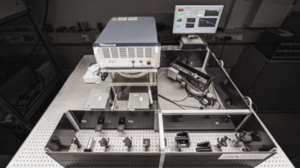

Cavity Ring-Down (CRD)

The CRD measurement method was developed to measure the reflectance of highly reflective mirrors (reflectances better than 99.99%) reproducibly and precisely. The strength of the CRD method is that - unlike conventional methods - it is independent of variations in the intensity of the light source. This allows the measurement of total optical loss to single digit ppm accuracy. Measurements are performed against the ISO 13142:2015 standard.

Our measuring station offers you measurements

- at1064 nm & 638 nm

- at angles of incidence 0°, 12°, 30°, 45°

- Any linear polarization

- Further angle settings possible with appropriate preparation of the system

For your quote request: Form CRD-Test

Scattered light measurement (Total Scattering)

The principle of total scattered light measurement is based on the integration of scattered radiation from flat surfaces by an integrating sphere. RhySearch has a FastTS measurement system from the Laser Zentrum Hannover with high sensitivity down to the ppm range. Samples up to four inches in diameter can be measured over the entire surface at a wavelength of 633nm - and with a short measurement time.

Further characterization and surface treatment offers

At RhySearch, various technologies are available for observing optical surfaces:

An automated Nomarski (DIC) microscope with a magnification range from 20x to 1000x, capable of operating in darkfield mode as well as brightfield. The microscope is also enhanced with a Sher interferometer. This allows the observation of surface topography, refractive index profiles, stresses and thickness differences of coatings.

An optical profilometer is available for determining surface roughness and shape. The instrument allows the measurement of flat and free-form parts using three possible methods: Focus Variation, Confocal Microscopy and Phase Shift Interferometry.

Both measuring devices can be used to evaluate optical surfaces and to observe coating- and substrate-induced defects.

Critical optical components must withstand the harshest conditions in industrial applications. At RhySearch, a climatic chamber that allows temperature tests between -70°C and 180°C as well as static humidity tests between 10% and 98% relative humidity is available. On request, tests with customized recipes can be carried out in it.

RhySearch has a nano-scribe tester for characterizing film-substrate systems and quantifying parameters such as adhesion strength and frictional force using a variety of complementary methods. It enables the determination of coating adhesion, scratch resistance and scratch strength for research, development and quality control.

An ion beam etcher (Ion Beam Milling) is used to produce mechanically undisturbed cross sections at precisely defined specimen locations and precision polishing of mechanically pre-polished specimen surfaces.

In addition, other various equipment such as an annealing furnace and a spectrophotometer are available for service orders.

Our website uses cookies so that we can continually improve the page and provide you with an optimized visitor experience. If you continue reading this website, you agree to the use of cookies. Further information regarding cookies can be found in the data protection note.

If you want to prevent the setting of cookies (for example, Google Analytics), you can set this up by using this browser add-on.