The production of dielectric optical coatings with low particle density remains a challenge and is becoming increasingly important to ensure high production yields and thus the competitiveness of Swiss companies. The consortium project PRACMATIC (Practical control and monitoring over time of dielectric coating processes) focuses on finding practical, industrial methods to eliminate particle formation during the deposition of dielectric coatings and on developing robust, easy-to-use and cost-effective in-process diagnostic tools and software to monitor the coating processes and particle generation.

The project, led by RhySearch, brings together seven industry and four research partners, is funded by Innosuisse, the Swiss Agency for the Promotion of Innovation, to the tune of just under one million Swiss francs and is scheduled to last until 2025.

What is PRACMATIC all about?

The demands on optical coatings are constantly increasing. They play a key role in many fast-growing markets, for example in laser technology or sensor technology.

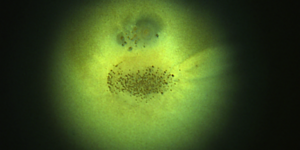

During the loading, unloading, closing or opening of a thin-film coating system, but also during the coating process itself, particles can be produced - unwanted small pieces of material with a size of 200 nm and more. These can affect the quality of coatings. Information about the distribution of particle sizes is important for both the deposited layers and the coating process.

In 2021, RhySearch - supported by the Innosuisse Photonics Booster - therefore initiated a consortium project with PRACMATIC to search for practical, industrial methods to eliminate particle formation during the deposition of dielectric coatings. The aim is to develop robust, easy-to-use and cost-effective in-process diagnostic tools and software to monitor the coating processes and particle generation. In this way, a process for the production of dielectric optical coatings with low particle density is to be defined in order to ensure a high production yield and thus the competitiveness of Swiss companies.

A detailed understanding of the problem and the necessary investigations was gained in two workshops held with the industrial and research partners as part of the PRACMATIC Innosuisse Photonics Booster project.

Joint project of industry and research

The PRACMATIC project combines expertise from both research and the production environments of the consortium partners along the entire process chain. Data is shared among them to make informed process decisions and to jointly develop, implement and test innovative processes. This will pave the way for future production processes that deliver predictable quality and enable the participating companies to produce coatings for the very highest demands for highly complex applications.

Partners involved:

- RhySearch

- Université de Neuchâtel

- BFH - Bern University of Applied Sciences

- OST - University of Applied Sciences of Eastern Switzerland

- FISBA AG

- SwissOptic AG

- Bühler AG

- Evatec AG

- SCHOTT Suisse SA

- Opcos AG

- Materion Optics Balzers

Contact: Heidi Thomé, Head of Optical Coating Division, +41 (0)81 755 49 66

→ to the "Optical coating" project overview

Our website uses cookies so that we can continually improve the page and provide you with an optimized visitor experience. If you continue reading this website, you agree to the use of cookies. Further information regarding cookies can be found in the data protection note.

If you want to prevent the setting of cookies (for example, Google Analytics), you can set this up by using this browser add-on.